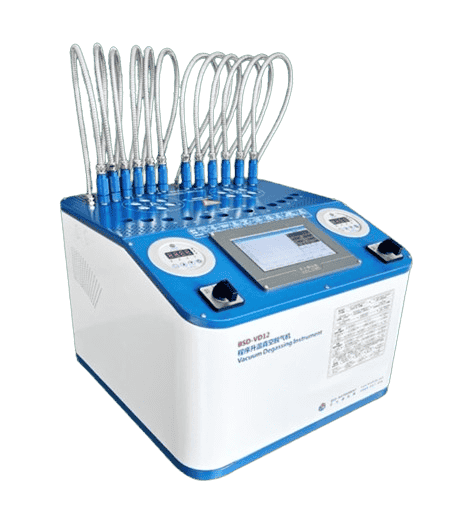

High-efficiency sample degassing unit with 12 positions, precise heating up to 400 °C, and stable high-vacuum control. Touch-screen controller with 32-step programmable heating ensures accurate and safe sample preparation.

- Built for reliability and sample protection.

- Pressure-based degassing completion detection for accurate monitoring.

- Optional cold trap protection for sensitive materials such as MOFs and COFs.

- Detailed degas curve logging for monitoring, recording, and review.

- Air-cooled and optional water-cooled positions to enhance operational flexibility.

- Supports inert backfill gases including helium, nitrogen, and argon for broad material compatibility.

- Seamless integration with BSD-660 and BSD-PH series analyzers.

- Ideal for research, quality control, and industrial laboratories.